Hubungi Kami

+86-19858305627

Email kami

sales@maple-machinery.com

Tuangan Besi Kekuatan Tinggi Pengilang

Kilang kami menyediakan pemutus pasir, penempaan die tertutup, penempaan die terbuka, dan lain-lain. Reka bentuk yang melampau, bahan mentah berkualiti, prestasi tinggi dan harga yang kompetitif adalah apa yang setiap pelanggan inginkan, dan itu juga yang kami boleh tawarkan kepada anda. Kami mengambil kualiti tinggi, harga berpatutan dan perkhidmatan yang sempurna.

Produk Panas

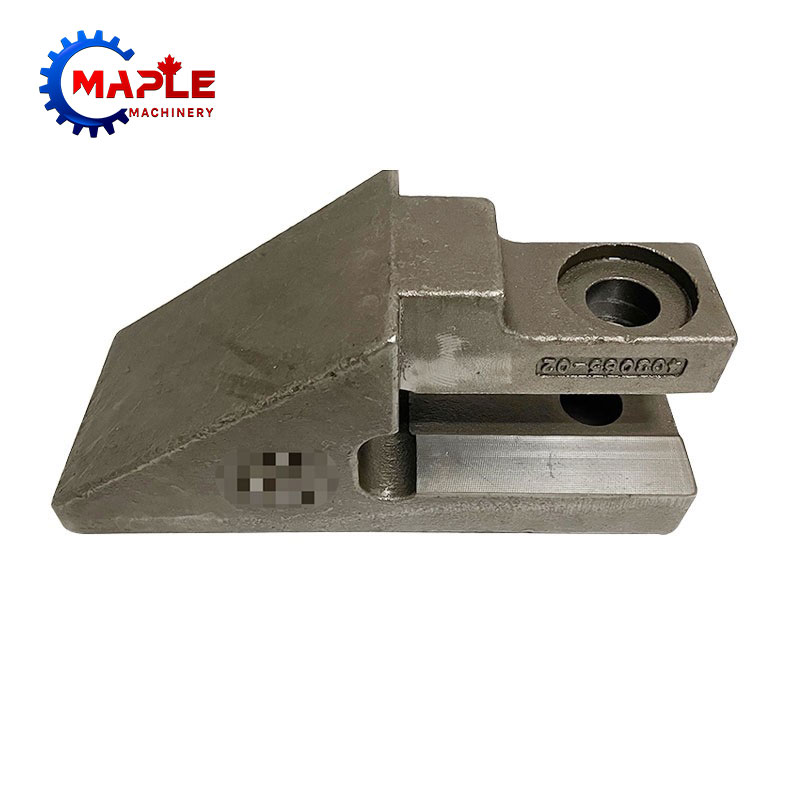

Bahagian Penempaan Keluli Tahan Karat Jentera Pertanian

Maple mempunyai lebih daripada 15 tahun pengalaman dalam pembuatan produk palsu untuk jentera pertanian. Bahagian Penempaan Keluli Tahan Karat Jentera PertanianKami boleh menghasilkan produk penempaan pertanian ketepatan melalui pemprosesan produk automatik. Memenuhi keperluan pelanggan yang berbeza. Kami menjamin prestasi produk kami. Sebaliknya, di bawah rangka kerja wawasan pelanggan dan pasaran, kami merancang dengan teliti untuk mengekalkan integriti rantaian bekalan dan bertindak balas terhadap keperluan pelanggan dalam keadaan terbaik.Bahagian Tuang Ketepatan Keluli Mesin Proses Makanan

Kami adalah pengeluar dan pembekal terkemuka dalam bidang Bahagian Tuang Ketepatan Keluli Mesin Proses Makanan. Rangkaian produk kami diperiksa kualiti mengikut pelbagai piawaian industri. Kami mempunyai lebih 15 tahun pengalaman dalam menyesuaikan bahagian untuk industri pemprosesan makanan. Kami menyimpan pelbagai jenis aci pemacu, pacuan, transmisi dan komponen. Kami telah melantik beberapa profesional berbakat. Pakar kami cuba memahami keperluan pelanggan.Bahagian Tuang Pasir Besi Industri

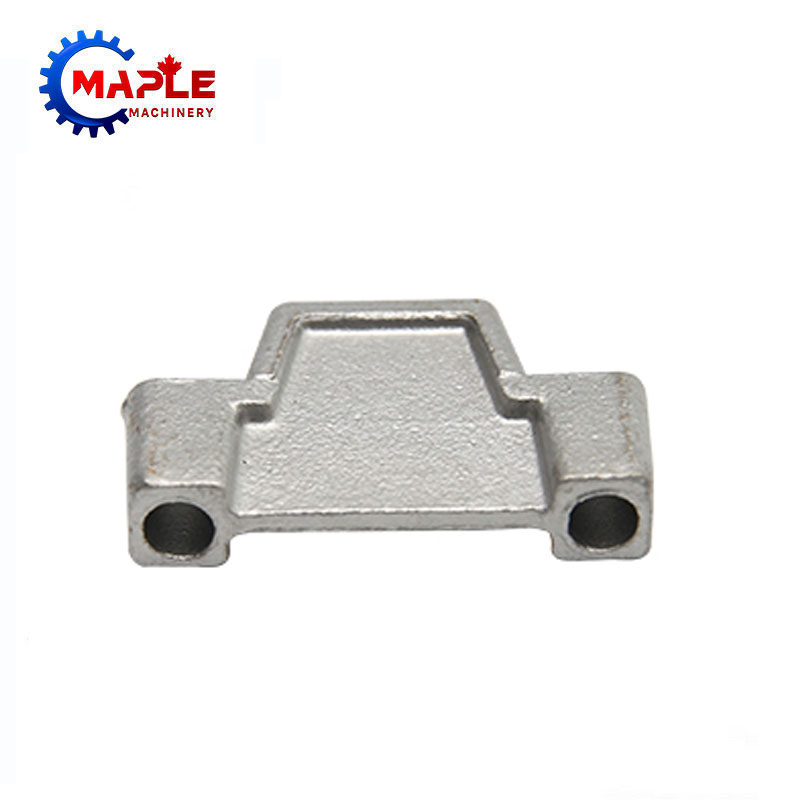

Jentera maple ialah pengeluar Bahagian Tuangan Pasir Besi Industri, yang mengkhusus dalam pengeluaran pelbagai jenis tuangan. Setiap firma ahli mempunyai pengetahuan khusus dan teknologi pengeluarannya sendiri. Semua faundri mempunyai aktiviti bebas mereka sendiri. Syarikat itu membuat Bahagian Tuang Pasir Besi yang dibuat khas untuk pelanggan globalBahagian Tempaan Die Tertutup Keluli Industri Luar Lebuhraya

MapleMachinery pakar dalam menghasilkan penempaan acuan tertutup. Produk kami termasuk penempaan logam seperti aluminium, keluli karbon, keluli aloi dan keluli tahan karat, yang digunakan dalam industri luar lebuh raya, pertanian, automotif, pembinaan dan perlombongan. Kami menyediakan Bahagian Penempaan Mati Tertutup Keluli Industri Luar Lebuhraya berkualiti tinggi dan jumlah kos terbaik melebihi jangkaan pelanggan.Bahagian Tuang Pasir Besi Industri Berat

Jentera maple, yang terletak di Ningbo, China, ialah faundri yang menghasilkan pelbagai Bahagian Tuangan Pasir Besi Industri Berat untuk aplikasi Industri Berat. Kami juga menghasilkan komponen enjin berprestasi tinggi, termasuk gelang omboh enjin diesel, pelapik silinder dan rod penyambung. Kami berbangga untuk mengatakan bahawa kami telah memperoleh reputasi sebagai pembekal beberapa penuangan Pasir Besi berkualiti tinggi di dunia. Kerana kualiti dan komitmen pelanggan kami direalisasikan untuk pelanggan.Mesin Proses Makanan Bahagian Penempaan Die Tertutup Keluli

Selama lebih daripada 15 tahun, jentera Maple mempunyai rekod prestasi yang terbukti dalam menyediakan haba, haus, hentaman dan penempaan tahan kakisan kepada pelbagai industri di seluruh dunia. Bahagian Penempaan Mati Tertutup Keluli Mesin Proses Makanan adalah salah satu daripadanya. Syarikat itu mempunyai perisian makmal dan simulasi yang paling canggih. Jurutera kami yang berpengalaman boleh menyediakan semua jenis penempaan berkualiti tinggi..

Hantar Pertanyaan

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy