Hubungi Kami

+86-19858305627

Email kami

sales@maple-machinery.com

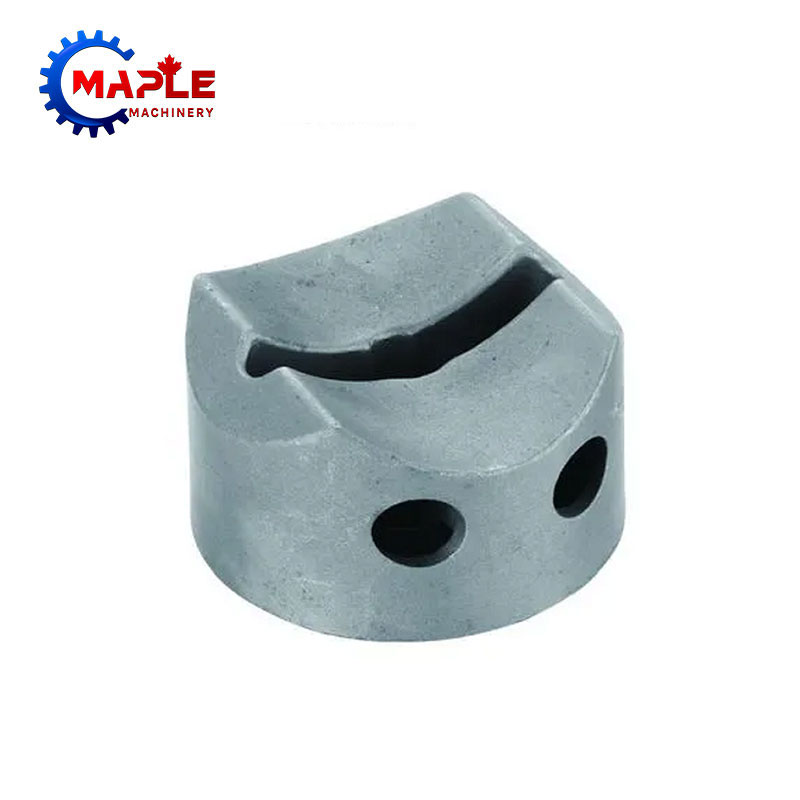

Komponen Tuangan Keluli Lembut untuk Industri Minyak & Gas Pengilang

Kilang kami menyediakan pemutus pasir, penempaan die tertutup, penempaan die terbuka, dan lain-lain. Reka bentuk yang melampau, bahan mentah berkualiti, prestasi tinggi dan harga yang kompetitif adalah apa yang setiap pelanggan inginkan, dan itu juga yang kami boleh tawarkan kepada anda. Kami mengambil kualiti tinggi, harga berpatutan dan perkhidmatan yang sempurna.

Produk Panas

Bahagian Tuang Ketepatan Keluli Mesin Proses Makanan

Kami adalah pengeluar dan pembekal terkemuka dalam bidang Bahagian Tuang Ketepatan Keluli Mesin Proses Makanan. Rangkaian produk kami diperiksa kualiti mengikut pelbagai piawaian industri. Kami mempunyai lebih 15 tahun pengalaman dalam menyesuaikan bahagian untuk industri pemprosesan makanan. Kami menyimpan pelbagai jenis aci pemacu, pacuan, transmisi dan komponen. Kami telah melantik beberapa profesional berbakat. Pakar kami cuba memahami keperluan pelanggan.Bahagian Tuangan Besi Kelabu Industri Minyak & Gas

Daripada jurutera Tuang Besi Kelabu, juruteknik, mandor, mekanik bangunan model dan pembina model dalam pengeluaran kepada juruteknik mekanikal dan elektronik industri atau pembantu pengurusan industri dalam penyelenggaraan, Mereka melakukan yang terbaik setiap hari untuk menggembirakan pelanggan Industri Minyak & Gas kami dengan tuangan berkualiti tinggi. Daripada perundingan dan pemprosesan pesanan, kepada penyediaan kerja dan pengeluaran bahagian tuangan besi kelabu Industri Minyak & Gas, kepada pemprosesan dan pengangkutan yang mendalam, sebagai satu pasukan, kami mengejar matlamat bersama: untuk menghasilkan bahagian tuangan besi kelabu yang kompleks dan berkualiti tinggiBahagian Penempaan Keluli Tahan Karat Kejuruteraan Awam

Kepentingan rasuk jenis keluli tahan karat dalam dunia pembinaan, kejuruteraan, pembinaan dan keluli struktur yang luas. Rasuk keluli tahan karat palsu telah menjadi bahagian penting dalam Kejuruteraan Awam selama lebih 15 tahun. Sebagai pembekal Bahagian Keluli Tahan Karat, jentera Maple menghasilkan pelbagai Bahagian Penempaan Keluli Tahan Karat Kejuruteraan Awam yang disesuaikan untuk anda oleh pasukan kami. Kami adalah pengeluar alat ganti anda yang dipercayaiBahagian Tuang Pelaburan Keluli Injap

Dalam jentera maple, kami mempunyai pengalaman Tuangan yang luas untuk Bahagian Tuang Pelaburan Keluli Injap, membolehkan pelanggan kami mendapatkan tuangan berkualiti tinggi daripada proses tuangan pelaburan pada kos yang menjimatkan. Kami mempunyai pasukan teknikal yang cemerlang dengan pengalaman bertahun-tahun untuk memberikan anda reka bentuk tuangan pelaburan terbaik. Sebarang bantuan yang diperlukan - daripada semakan toleransi mudah kepada kejuruteraan serentak penuh - boleh didapati di tapak faundri kami. Bahagian Tuang Pelaburan Keluli Injap, jentera maple boleh memberikan anda yang terbaik.Bahagian Tuang Ketepatan Keluli Industri Perlombongan

Jentera Maple amat menyedari bahawa penggerudian dan perlombongan adalah industri berkekuatan tinggi, jadi mereka memerlukan Bahagian Tuang Ketepatan Ketepatan Keluli Industri Perlombongan yang boleh memenuhi spesifikasi bahan yang ketat. Jentera maple bukan sahaja boleh membantu anda membuat tuangan, tetapi juga membantu anda menukar bahagian kimpalan kepada tuangan dan menambah baik reka bentuk. Kami mengoptimumkan sifat mekanikal bahagian melalui reka bentuk tuangan, pemilihan aloi dan proses rawatan haba, dan memastikan sifat-sifat ini dipenuhi oleh pasukan kualiti dalaman kami yang diperakui dan kemudahan ujianMinyak & Gas Bahagian Penempaan Keluli Industri

Selama beberapa dekad, jentera Maple telah menjadi pembekal utama kepada industri Minyak dan Gas, memberikan harga yang berkualiti tinggi dan kompetitif. Disebabkan oleh keadaan persekitaran yang teruk dalam industri Minyak dan Gas, industri keretakan bawah air, permukaan dan hidraulik, Maple memastikan bahan berkualiti tinggi dan ketepatan penempaan melalui sumber penempaan, keupayaan dan pengalaman, serta menghasilkan Bahagian Penempaan Keluli Industri Minyak & Gas terbaik dalam masa penghantaran yang paling singkat.

Hantar Pertanyaan

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy